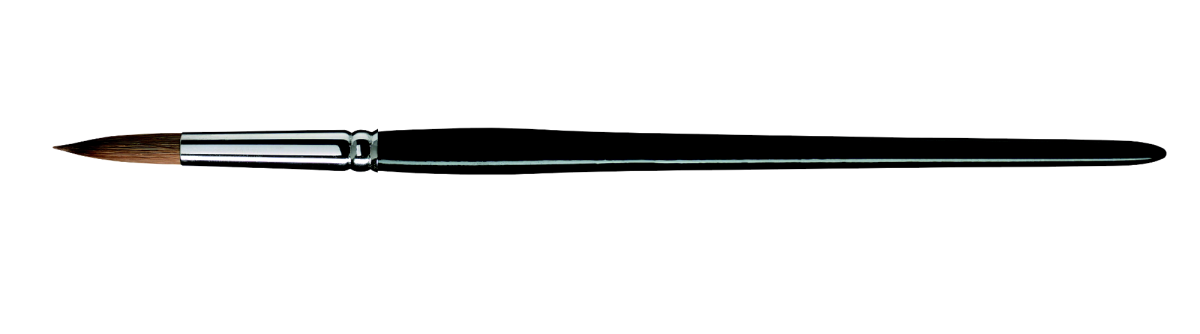

Brushes

Cleaning, derusting, deburring, descaling, moistening, polishing, structuring, dedusting, brushing, sorting, sprinkling, powdering, roughening, smoothing, removing, distributing, waxing, transporting, oiling, washing, grinding, surface finishing ….

The wide range of uses in almost all industrial sectors is shown by the industries listed below:

Rolling mill industry, metal processing industry, wood processing industry, food industry, textile industry, building materials industry, ceramics industry, plastic and film processing industry, glass industry, automotive industry, etc.

Mida Brush has round brushes for a wide range of applications. The dimensions, body and fill materials depend entirely on the location, purpose and conditions of use.

For special cases, we are able to produce custom-made brushes according to your specifications. In doing so, we adapt body shape, material as well as type and design of the trim, but also mounting threads and ball bearings or axle bores with keyways or pins to you requirements. Based on your drawings or in discussion with you, we will work out your individual brush solution.

Strip Brushes

Strip brushes usually consist of a square basic body which is bristled on one side. Strip brushes can be supplied with additional fastening aids such as holes, threads, longitudinal holes, inner square and angled flange. Also as a prefabricated profile according to drawing.

The trim material is either punched by machine or drawn in by hand. Mounting holes, shank or thread are manufactured according to specification. Fill density and fill arrangement (full fill, field fill) depend on the intended use.

Disc Brushes

Disc brushes consist of a round, flat basic body. Frequently used materials are plastic (PE, PVC and PP) and wood (beech, plywood). For certain applications, steel and precious and light metals are also used. All common fill materials can be used as fill types.

The facing material is either punched by machine or drawn in by hand. Mounting holes, shanks or threads are manufactured according to the specifications. Fill density and fill arrangement (full fill, field fill) depend on the intended use.Management by the great-grandchildren of the founder, Christine and Paul Mida.